There’s a reason headlight forums are full of arguments: one person says “I dropped in LED bulbs and it’s amazing,” another says “it’s glare city and I can’t see in rain,” and a third warns you’ll cook your housing or fail inspection. Everyone’s telling the truth—for their specific headlight design.

If you’re starting with halogen headlights (and most older cars did), the upgrade path isn’t one-size-fits-all. The housing type—reflector bowl vs projector—decides whether a simple bulb swap is a harmless cosmetic change or a safety problem. And if your car already has OEM LED headlights, things get even more technical because the car’s computer is watching everything you touch.

Leding works from the factory side of this world: parts design, assembly, retrofit compatibility, and what actually survives heat, vibration, and daily use. Below is the straight, practical breakdown.

The Question Everyone Asks: Can You Put LED or HID Bulbs in Stock Halogen Headlights?

Let’s answer this without dancing around it: sometimes you can, but often you shouldn’t. And the deciding factor isn’t your courage—it’s your optics.

Two common types of stock halogen headlights

1) Reflector bowl (“lamp bowl”) halogen headlights

This is the classic open reflector design—think older sedans and many entry models. The halogen bulb was designed as part of the optical system, and the reflector geometry expects the halogen filament to sit at a very specific focal point.

When you install a random LED bulb or HID bulb:

- The focal point is different from a halogen filament.

- The reflector can’t control the light properly.

- You get scatter and glare: bright to look at, worse to drive with.

- The beam pattern often becomes “bright noise” instead of usable distance.

- Heat distribution can change, and uneven heating can damage surfaces over time.

This is why you see the classic complaint: “It’s brighter, but I can’t see the road.” You’re lighting up everything except the place you need—down the lane, with a controlled cutoff.

Factory-minded advice: If you have reflector-bowl halogens, don’t do a bulb swap expecting a real upgrade. It’s the fastest way to create glare and waste money.

2) Halogen projector headlights (stock projector with a halogen bulb)

This is the other case: the car came with a projector lens system, but uses a halogen bulb as the light source.

A projector has better optical control than an open reflector bowl. If you swap the halogen bulb for an LED bulb or HID bulb (same base type), you will usually see:

- whiter color

- more apparent brightness

- a cleaner cutoff (sometimes)

But here’s the part nobody likes to hear: the beam width and distance often don’t truly change. You might get more “white foreground,” but not more safe seeing distance. It can feel impressive in a parking lot and disappointing on a dark highway.

So yes—on halogen projector headlights, a bulb swap can be “acceptable” as a temporary step. It’s just not the best way to get a serious performance jump.

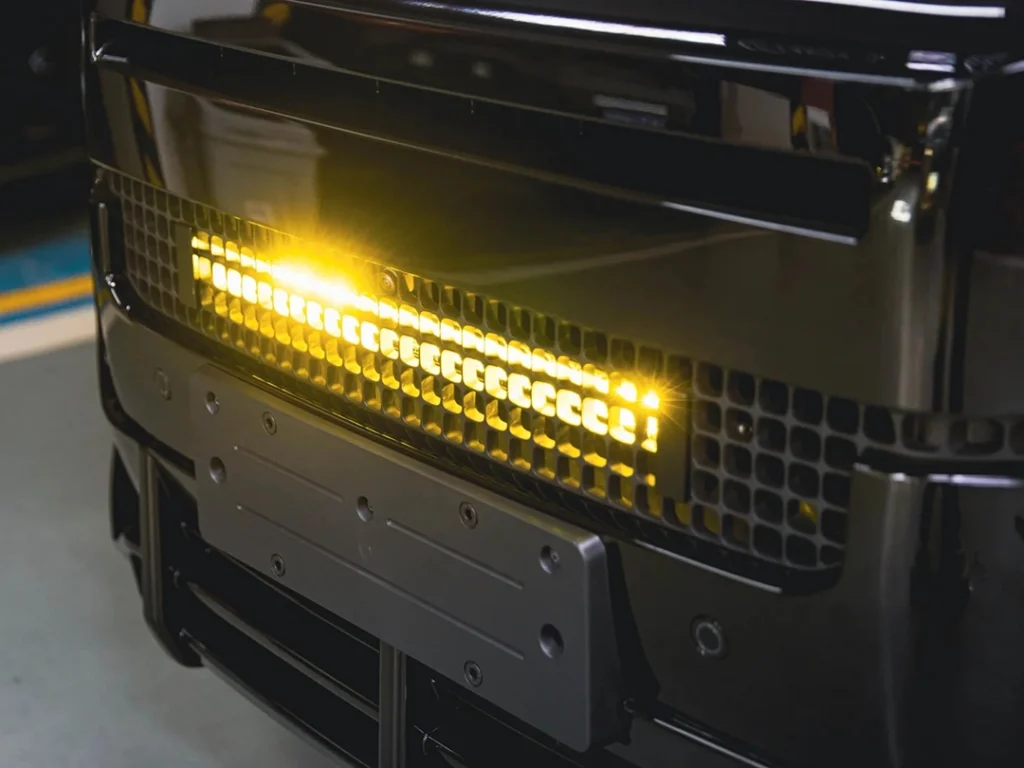

The Real Upgrade Is Optics: LED Projector Headlights for Cars (and Why Projectors Matter)

If your goal is to actually see better—not just look brighter—then the upgrade isn’t the bulb. It’s the projector.

A proper bi-function projector (high/low in one unit) is designed to:

- concentrate light where it belongs

- create a stable cutoff line for low beam

- put usable intensity downrange (distance)

- control glare so other drivers aren’t blinded

That’s why, in real terms, adding a quality bi-function projector can produce a major jump in usable illumination compared with halogen—often multiple times more effective on-road, especially in distance and uniformity.

Why “just bulbs” are the wrong tool for a beam-pattern problem

Swapping bulbs is like changing the speaker in a bad room and hoping the echo disappears. The “room” (your headlight optics) still shapes the result.

Projectors are purpose-built optics. Done correctly, they’re the difference between:

- bright-but-messy light that annoys traffic

- and a clean, long-reaching beam that makes night driving less stressful

Projector Headlights vs LED: The Comparison People Get Backwards

This is where online arguments get silly, because the comparison is often framed wrong.

People say “projector headlights vs LED,” as if projector and LED are opposing choices. They’re not.

- Projector = the optical system (lens + shield + reflector bowl inside the module)

- LED = the light source technology

So the real comparisons are usually:

- reflector halogen vs projector halogen

- projector halogen vs projector HID

- projector HID vs projector LED

- OEM LED module vs retrofit projector LED module

Once you separate optics from light source, the decisions get clearer.

What actually matters on the road

In a factory environment, we judge a headlight upgrade by:

- cutoff sharpness and stability

- foreground balance (not too bright close-up)

- width (lane coverage)

- distance (high beam reach, low beam usable throw)

- glare control

- thermal reliability (won’t fade, yellow, or warp)

- electrical stability (no flicker, no errors, no random shutdowns)

Color temperature and “wow brightness” are last—because they’re easiest to sell and easiest to misunderstand.

LED vs HID Retrofits: Same Workflow, Different Product Reality

From the outside, LED retrofits and HID (xenon) retrofits look like different worlds. In a professional shop, the workflow is basically the same:

- open the housing

- mount the projector

- test beam pattern

- adjust aim and alignment

- clean inside surfaces

- reseal properly

- verify electronics and function

- final aiming on a standard setup

Where the difference shows up is the hardware behavior and installation complexity.

1) Packaging: LED is usually cleaner

With HID systems, you typically deal with:

- separate ballasts/igniters

- extra wiring and mounting locations

- more points of failure if done sloppy

With modern LED projector modules, the integration is tighter. Many are designed with fewer external components, so install can be faster and neater—if the module is well designed.

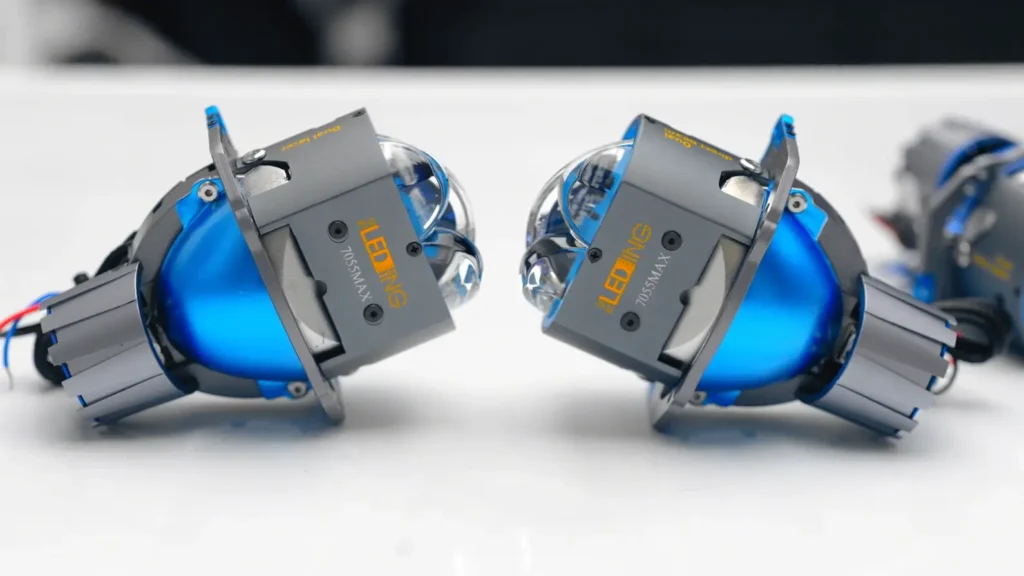

2) Brightness consistency: LED modules are more “pre-tuned”

With HID retrofits, you often need careful matching between:

- bulb position

- projector focal characteristics

- and sometimes bulb brand/batch variation

A quality LED projector module is generally tuned at the factory—LED position, reflector geometry, and shield work as a set. That’s why LED projector upgrades can feel more consistent when done with proper components.

3) What customers perceive: LED usually “looks” like a bigger jump

LED has become the mainstream choice because it tends to deliver:

- higher perceived brightness

- crisp color (without needing extreme color temps)

- fast response

- modern visual signature

That said, a well-built HID projector system can still perform extremely well. The key isn’t “LED vs HID” as a slogan—it’s whether the optics, alignment, and thermal design are right.

Why Bulb Swaps Often Create Glare (Even When the Owner Swears It’s Fine)

This is the awkward truth: most drivers evaluate their headlights from the driver’s seat only. They don’t stand 30 meters ahead in a dark lane and see what oncoming traffic sees.

Glare happens when:

- the source size/position doesn’t match what the optics expect

- the cutoff shield can’t control the stray light

- the reflector “sprays” uncontrolled light upward

- the bulb claims high lumens, but the beam puts lumens in the wrong place

A “bright” headlight with poor optics creates visual discomfort for others and can even reduce your own ability to see far (because the bright foreground makes your eyes adapt, shrinking your night vision).

If your upgrade makes road signs explode with brightness but doesn’t extend clean visibility down the lane, that’s not a win. That’s a light show.

Upgrading Stock LED Headlights: Yes, It’s Possible—But It’s Not a DIY Bulb Game

Now let’s talk about newer cars. Many vehicles now come with LED headlights from the factory. Owners still complain:

- low beam feels narrow

- high beam doesn’t reach far enough

- the “LED” is modern but the performance isn’t impressive

That’s not your imagination. Many OEM LED systems prioritize:

- cost targets

- packaging constraints

- regulatory compliance

- long life and low warranty risk

So the upgrade question becomes: can you retrofit better projectors (LED/HID/laser-style modules) into an OEM LED headlight assembly?

In many cases: yes—there is physically enough space and the optical upgrade can be done.

But this is where “internet tutorial confidence” meets the real world.

OEM LED systems are controlled by the vehicle computer

Modern LED headlights often involve:

- CANBUS monitoring

- load detection

- communication between headlight module and ECU/BCM

- error checking (bulb-out, overheating, abnormal current draw)

If you change modules without proper decoding/resistors/drivers (depending on the car), you can trigger:

- dashboard errors

- flicker

- reduced power / limp lighting mode

- random shutdown

- unreliable DRL/turn/high-beam functions

This is why small shops sometimes “get it working” on day one, then the customer comes back a week later with errors, condensation, or a headlight that behaves like it’s haunted.

The Two Non-Negotiables for OEM LED Retrofits (Factory Perspective)

From a projector headlights factory viewpoint, there are two points you can’t shortcut.

1) Every headlight assembly is different—space and structure decide difficulty

Even within the same brand, different trims and years can have totally different:

- internal bracket geometry

- heat sinking space

- lens depth

- leveling motor placement

- wiring path and sealing design

Some headlights accept a retrofit projector cleanly. Others require serious fabrication and precise alignment work. If you force it, you risk:

- cracked mounts

- misaligned cutoff

- vibration-induced failure

- permanent housing damage

And yes—those assemblies can cost anywhere from “painful” to “why is this more than my rent.”

2) Decoding and electronics aren’t universal

Some cars require:

- dedicated decoders

- module programming/coding

- specialized testing equipment

- correct drivers matched to the car’s monitoring logic

A shop that does this properly will talk about testing, fault scanning, and stability—not just “plug and play.”

A shop that doesn’t… will often promise plug-and-play anyway.

Where People Waste Money: The Three Most Common Upgrade Mistakes

Let’s save you from the classic traps.

Mistake #1: Buying the brightest bulb and hoping optics don’t matter

If your housing is a reflector bowl, this is the fastest route to glare and disappointment.

Mistake #2: Treating “white light” as “better light”

Whiter can look nicer, but rain/fog performance and downrange contrast depend on beam quality, not just color.

Mistake #3: Choosing a shop based on photos alone

A retrofit photo can look perfect and still be:

- mis-aimed

- poorly sealed

- prone to condensation

- electrically unstable

- inconsistent between left and right beam

Good work shows up at night, on the road, after months—not only on social media.

Practical Upgrade Paths (Based on What You Have)

This is the decision tree most car owners actually need.

If you have reflector-bowl halogen headlights

- Skip bulb swaps as a “solution.”

- Consider a proper bi-function projector retrofit.

- If budget is limited, save until you can do optics, not just bulbs.

If you have halogen projector headlights

- A bulb swap can be a temporary improvement (whiter/brighter look).

- A projector upgrade is what changes width/distance meaningfully.

- Don’t expect miracles from bulbs alone.

If you have OEM LED headlights

- Upgrades are possible, but they’re electronics + optics, not “bulb upgrades.”

- Choose a professional shop with decoding capability and model-specific experience.

- Confirm how errors are handled and how sealing is guaranteed.

What a Professional Retrofit Should Include (Even If the Shop Doesn’t Brag About It)

A proper job is boring in the best way: clean, repeatable, tested.

Look for these habits:

- beam pattern testing before final sealing

- careful internal cleaning (dust inside a projector is forever)

- quality butyl/sealant work and venting checks

- stable wiring routing and secure mounting

- left/right symmetry checks

- final aiming using a controlled distance and reference marks

If a shop talks only about “brightness” and not about cutoff, glare, sealing, and electronics stability, that’s a warning sign dressed up as marketing.

The Takeaway: Want Better Night Driving? Upgrade the System, Not the Bulb

The internet loves quick hacks. Headlights punish quick hacks.

If your goal is real performance—safer lane visibility, controlled cutoff, long reach, and fewer surprises—then the most rational route is:

- prioritize optics (projectors)

- choose a proven light source system (often LED projector modules today)

- match it to your car’s housing and electronics properly

That’s why LED projector headlights for cars have become the mainstream retrofit choice: when designed and installed correctly, they deliver modern output and controlled beam quality.

And that’s also why the “projector headlights vs LED” argument misses the point. The best setups are projector + LED, engineered as a system—not a bulb tossed into a housing that was never designed for it.