Walk into almost any retrofit shop and you’ll hear the same line: “If you want real light, you need a projector.” True. Then comes the part that turns into trouble: “Projectors are basically universal.” Sometimes true-ish. Often dangerously oversimplified.

This pillar guide unpacks what a projector actually is, why some auto projector headlights upgrades feel like night-and-day while others feel like a bright disappointment, and how to think clearly about bi projector headlights, the increasingly common biled projector headlight, and the hype (and reality) of a laser projector headlight. I’ll keep it practical, like the conversation you wish you had before you paid for a retrofit.

What “Projector” Really Means (And Why It’s Not Just “A Lens”)

People use “lens” and “projector” like they’re interchangeable. In retrofit terms, a projector is an optical system designed to shape light into a controlled beam pattern—especially that clean low-beam cutoff everyone loves.

A typical projector module includes:

- A reflector bowl (collects and directs light forward)

- A cutoff shield (creates the low-beam cutoff line)

- A convex front lens (projects the shaped beam onto the road)

- A light source (halogen, HID/xenon, LED, or laser-driven systems)

- On bi-function units: a solenoid (electromagnet) + movable shield/flap to switch low/high beam

When someone says “add a projector,” they usually mean upgrading the entire optical module, not just slapping in a different bulb.

Why projectors matter more than “brightness”

Night driving isn’t a contest of raw lumens. What you feel as “good headlights” is mostly:

- Where the light lands (down-road vs into trees and mirrors)

- How evenly it spreads (no dark holes)

- How controlled it is (minimal glare above cutoff)

A great projector can make a modest light source feel strong. A bad optic can waste a powerful light source and irritate everyone coming the other way.

Single vs Bi: The Only Projector Difference Most Drivers Need to Understand

Before we talk LED vs HID vs laser, you need the basic classification:

Single-beam projectors (often “low-only”)

A single-beam projector is designed for either low beam or high beam—not both.

- Many factory halogen projectors are low-beam-only

- Some OEM LED or HID systems also use single-beam modules depending on trim

In the real world, many older single-beam projectors don’t impress because:

- reflector coatings age

- internal parts oxidize or haze

- the optical design is built to a budget

That’s why a “has a projector” headlight can still be mediocre after a few years.

Bi projector headlights (bi-function)

Bi projector headlights use one projector to do both low and high beam. The key is the solenoid-controlled cutoff mechanism:

- In low beam, the shield blocks upward light, creating a cutoff

- In high beam, the shield flips/moves so more light is allowed upward and outward

This is the upgrade most shops mean when they say “retrofit a projector,” because it’s a two-for-one improvement: low beam gets cleaner and wider, and high beam can actually reach.

Quick visual clue (in plain language)

If a projector has a solenoid and a moving shutter mechanism, it’s typically bi-function. If it doesn’t, it’s usually single-beam.

Auto Projector Headlights: What Actually Makes a “Good” Projector?

“Projector” is a category, not a quality guarantee. Two projectors can look similar and perform wildly differently.

The performance checklist that matters on the road

A strong projector setup typically delivers:

- Sharp, stable cutoff (not fuzzy, not wavy)

- Wide low beam (fills the lane and shoulder)

- Useful hot spot (a brighter center area that reaches)

- Even distribution (less patchiness)

- Good high beam (not just “more glare,” but more distance)

The boring stuff that separates “good” from “regret”

- Coating quality on the reflector bowl (heat resistance + reflectivity retention)

- Lens clarity and proper alignment

- Thermal design (especially for LED)

- Mechanical rigidity (vibration kills aim consistency)

- Sealing and venting (condensation is the slow death of optics)

If you’ve ever seen a car with “expensive headlights” that look foggy or uneven, odds are the optical surfaces and sealing weren’t treated as seriously as the marketing.

“Are Projectors Universal?” The Honest Answer (It Depends on What You Mean)

This is where shops and customers talk past each other.

What can be “universal” in practice

Many retrofit-oriented bi-function projectors follow common mounting patterns and can be adapted to a wide range of housings. That’s why you’ll hear claims like “fits most cars.”

In many cases, yes—a bi projector retrofit can be made to work in the majority of vehicles, especially those with enough internal space and conventional headlight architecture.

What is not universal (and causes surprise costs)

Even if the projector’s mounting is “universal,” your headlight assembly may not be:

- Space constraints: depth behind the lens, clearance near the reflector, room for heat sinks/drivers

- Bracket geometry: factory mounting points rarely match aftermarket hardware perfectly

- Lens position and shrouds: cosmetic fitment isn’t guaranteed

- Vehicle electronics: DRLs, CANBUS monitoring, adaptive systems, leveling motors

- Advanced OEM tech: matrix/AFS/ADB systems can complicate everything

So the truth is:

- The projector unit may be broadly adaptable

- The car is the limiting factor

A good shop talks about the headlight housing like a tiny apartment: sure, you can buy a new sofa, but it still has to fit through the door and not block the kitchen.

The Four Light Sources (Halogen, HID, LED, Laser) — Without the Hype

Projectors are optics. Light sources are the “engine.” The best results come from matching the two.

Below is a grounded breakdown of the four common technologies used in projector setups.

Halogen: Cheap, Predictable, and (Mostly) the Past

Halogen is basically the upgraded version of the incandescent concept: a filament inside a gas-filled capsule designed to run hot and stable.

Why halogen stuck around for so long

- Low cost

- Easy to control electrically

- Reliable enough

- Color can cut through some weather conditions decently

Why people upgrade away from it

- Lower efficiency (more power for less light)

- Yellowish color

- Limited reach (especially in basic optics)

- Heat load on housings

A halogen projector can be “fine,” but it rarely feels premium unless everything else is optimized—and most factory halogen setups are built to a price point.

HID (Xenon): The Classic Retrofit Workhorse

HID stands for High Intensity Discharge. Instead of a filament, it creates light via an arc in a capsule, powered by a ballast that steps up voltage dramatically.

Why HID became the retrofit darling

- Strong output (often a big jump over halogen)

- Efficient for its era

- Pleasant, daylight-ish beam when done right

The trade-offs people forget

- Needs quality ballasts and proper wiring

- More components = more potential failure points

- Warm-up time (not instant full brightness)

- Beam quality depends heavily on the projector designed for HID

A great HID projector setup can still be excellent. But in 2026, many drivers choose LED modules because packaging and consistency are easier.

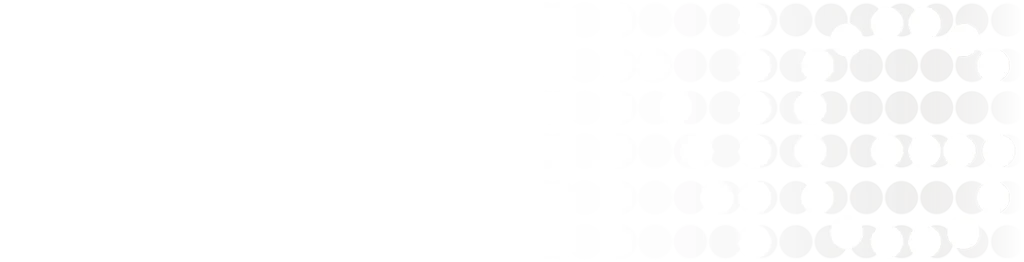

Biled Projector Headlight: Why Bi-LED Took Over Retrofits

A biled projector headlight typically means:

- a bi-function projector (low + high via solenoid)

- with an integrated LED light source designed as part of the module

This is the big shift versus “LED bulbs in a halogen housing.” In a Bi-LED projector, the LED chips, reflector geometry, cutoff shield, and lens are engineered as a system.

Why Bi-LED projectors are popular in real installs

- Compact packaging (often fewer external parts than HID)

- Instant on/off (nice for high beam response)

- Stable color and output when properly cooled

- Factory-tuned alignment between emitter position and optics

The important caveat: LED success is thermal success

LED performance is tied to heat management. If cooling is weak, you’ll see:

- output drop after it heats up (thermal throttling)

- faster degradation

- color shift over time

A quality Bi-LED module is as much a heat sink and driver design problem as it is an “LED brightness” problem.

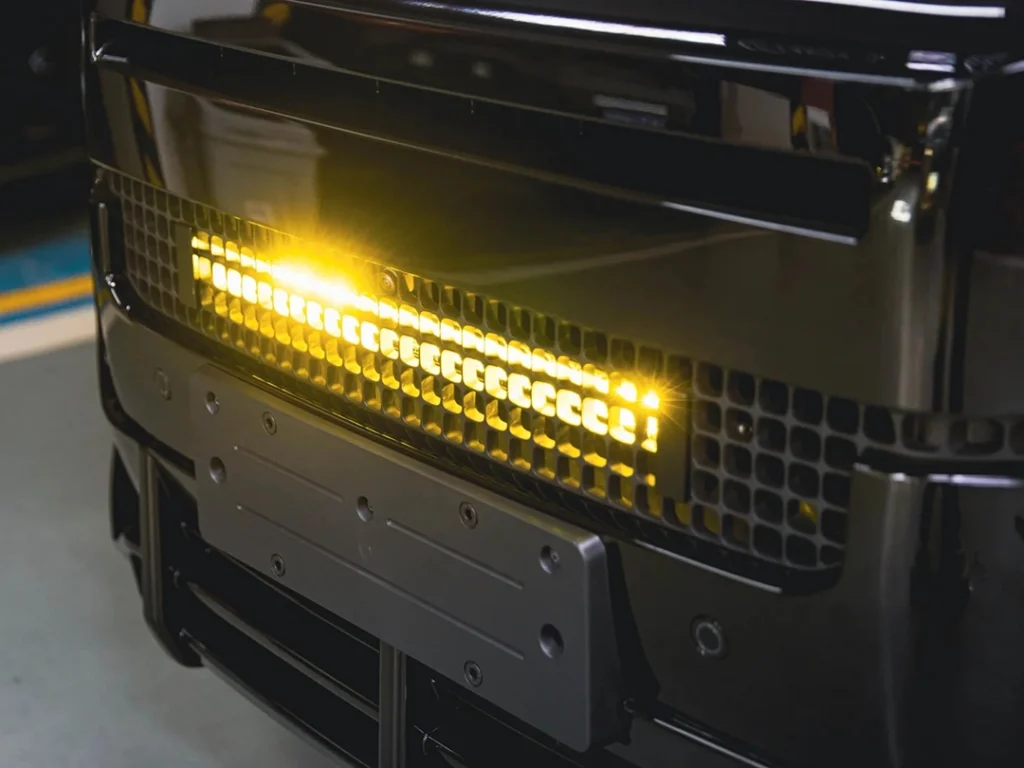

Laser Projector Headlight: What It Is, and Why It’s Not a Magic Upgrade

“Laser headlight” gets thrown around like it means “brightest thing possible.” In modern automotive use, laser systems usually work like this:

- Laser diodes generate energy

- That energy hits a phosphor element

- The phosphor emits intense white light

- Optics shape it into a beam (often for high beam assist)

Why laser is usually seen on high-end cars

- High intensity potential in a small package

- Great for long-range high beam performance

- Engineering complexity (and cost) are high

Why laser is rare as a casual retrofit choice

- Cost is significantly higher

- Packaging and safety requirements are stricter

- Integration with OEM systems can be difficult

- Not every housing can support the thermal and mechanical needs

Laser is impressive tech, but for most daily drivers seeking a practical improvement, a well-designed Bi-LED projector retrofit is often the smarter cost-to-performance play.

The “Ranking” Argument: Is It Really Halogen < HID < LED < Laser?

You’ll often see a simple ladder like: halogen < HID < LED < laser

As a technology trend, that’s broadly the direction the industry moved. But on the road, what matters is the full system:

- a mediocre LED projector can lose to a great HID projector

- a “laser” badge doesn’t guarantee better low beam

- a great optic with decent output beats a bad optic with huge output

So yes, higher-end tech often enables higher performance—but it doesn’t guarantee it.

Why OEM Single Projectors Often Underperform (Even When Everything Is “Stock”)

This is the part that surprises people: factory projectors can be disappointing, especially on lower trims.

Common reasons:

1) Cost and compliance targets

OEMs design to:

- meet regulations

- hit warranty life

- stay within cost and assembly constraints

The result can be a safe, acceptable beam—not an enthusiast beam.

2) Aging inside the housing

Over time:

- reflector bowls can oxidize or dull

- internal haze and micro-dust reduce clarity

- seals weaken and moisture accelerates degradation

A projector system is optical. Optical systems hate contamination. A little haze can steal more usable light than you’d expect.

3) Conservative tuning

Many OEM setups avoid aggressive output to reduce:

- heat stress

- glare complaints

- long-term degradation

- variability across production

That’s why upgrading the projector module (not just the bulb) can feel like the real unlock.

“Universal Fit” vs “Professional Fit”: What a Good Retrofit Actually Requires

Even if a projector module can physically fit, professional-level results come from alignment and verification.

Mechanical fitment (the part everyone talks about)

- mounting brackets and hardware

- centering the projector

- ensuring it sits square and stable

- shroud fit and appearance

Optical fitment (the part that makes or breaks it)

- cutoff level and straightness

- left/right symmetry

- hotspot placement

- beam width and shoulder fill

Environmental fitment (the part that decides longevity)

- resealing properly

- checking vents/breathers

- preventing condensation

- securing wiring away from heat and moving parts

A retrofit can look clean on day one and still fail because sealing and venting were treated as an afterthought.

Choosing Between Bi-LED, HID Bi-Xenon, and Laser: A Practical Buyer’s Guide

Here’s a quick comparison framed like a real decision, not a brochure.

If you want the most balanced daily-driver upgrade

Biled projector headlight retrofits are often the best mix of:

- performance

- clean install

- quick response

- lower component count

If you prioritize proven performance and don’t mind extra hardware

Bi-xenon (HID) projectors can still deliver excellent distance and width—especially when:

- the projector is designed for HID

- ballasts and bulbs are quality

- installation is tidy and reliable

If money is no object and you’re chasing long-range high-beam tech

A laser projector headlight setup is compelling—but usually makes sense when:

- the vehicle platform supports it well

- integration is done by specialists

- expectations are realistic (often strongest for high beam systems)

The Biggest Retrofit “Gotchas” That Aren’t About Brightness

This section saves people from the classic regrets.

1) Space isn’t just “will it fit?”

It’s also:

- will the rear cover close?

- will the heat sink breathe?

- will wiring clear moving parts?

- will the projector sit at the correct depth for focus?

2) Not all “bi” projectors give good high beam

Some bi-function modules have:

- great low beam

- mediocre high beam throw

A real high beam should add distance, not just “more light everywhere.”

3) Electronics can complicate modern cars

On newer vehicles, you may deal with:

- CANBUS checks

- bulb-out warnings

- DRL behavior changes

- flicker from PWM signals

A quality install anticipates this rather than improvising after the dashboard lights up like a Christmas tree.

4) Condensation is the silent killer

Poor sealing and venting cause:

- fogging

- corrosion

- dull reflectors

- hazed lenses

This is why “cheap retrofits” can look amazing for a month and then steadily decline.

A Simple “Does My Car Need a Projector?” Checklist (Real-Life Edition)

If you’re debating whether to retrofit, this is a practical way to decide.

You probably need a projector upgrade if:

- your low beam has no clean cutoff and throws glare

- you’ve tried bulb swaps and still can’t see distance

- your beam is narrow with dark edges

- your headlights look cloudy inside or weak despite “working”

You might not need a full retrofit if:

- your OEM projector is strong and only the bulb is tired

- your aim is clearly off (many “bad headlights” are just mis-aimed)

- your lenses are hazed externally and need restoration first

Sometimes the best “upgrade” starts with correcting aim and restoring the outer lens. Not glamorous, but it can change everything.

What to Ask a Shop (So You Don’t Get Sold a Buzzword)

If a shop is pushing auto projector headlights upgrades, the smartest customers ask boring questions:

Fitment and optics

- How do you ensure the cutoff is level and centered?

- Do you test beam pattern before final sealing?

- What projector model is being used (not just “Bi-LED”)?

Sealing and reliability

- What sealant is used, and how is condensation prevented?

- Are vents checked or modified if necessary?

- What warranty covers moisture or internal haze?

Electronics (especially for newer cars)

- How do you handle errors, flicker, and DRL behavior?

- Is decoding needed for this specific model?

A professional answer sounds calm and specific. A shaky answer sounds like “don’t worry, it’s plug and play.”

Key Takeaways (The Version You’ll Remember a Month From Now)

Projector retrofits aren’t mysterious—they’re just optics, mechanics, and electronics done correctly.

- A projector is more than a lens; it’s a complete beam-shaping system.

- Bi projector headlights add real function (low + high), not just a brighter look.

- A biled projector headlight works best when LED + optics are engineered together, not mixed-and-matched.

- A laser projector headlight is impressive tech, but rarely the most practical first upgrade.

- “Universal” is a half-truth: many projectors are adaptable, but the headlight housing and vehicle electronics decide the real difficulty.

If you treat headlights like a system—not a bulb—you end up with light that’s not only brighter, but actually useful, controlled, and comfortable to drive with.