Most people don’t start researching projector headlights because they’re bored. They do it after a tense night drive in the rain, after realizing their low beams feel like two candles, or after getting flashed by oncoming drivers even though they swear they’re not using high beams. That’s the moment the internet gets loud: “best bulbs,” “brightest kit,” “plug-and-play.”

But if you want an upgrade that feels factory—clean beam pattern, no warnings, no fogging, no messy wiring—then the conversation has to shift from products to process. This pillar guide explains what is projector headlamp, breaks down projector headlamps vs halogen, touches on laser projector headlight technology, and lays out the professional installation workflow behind OEM projector headlights—the kind of workflow you’d expect from a serious projector headlights factory and a disciplined retrofit team.

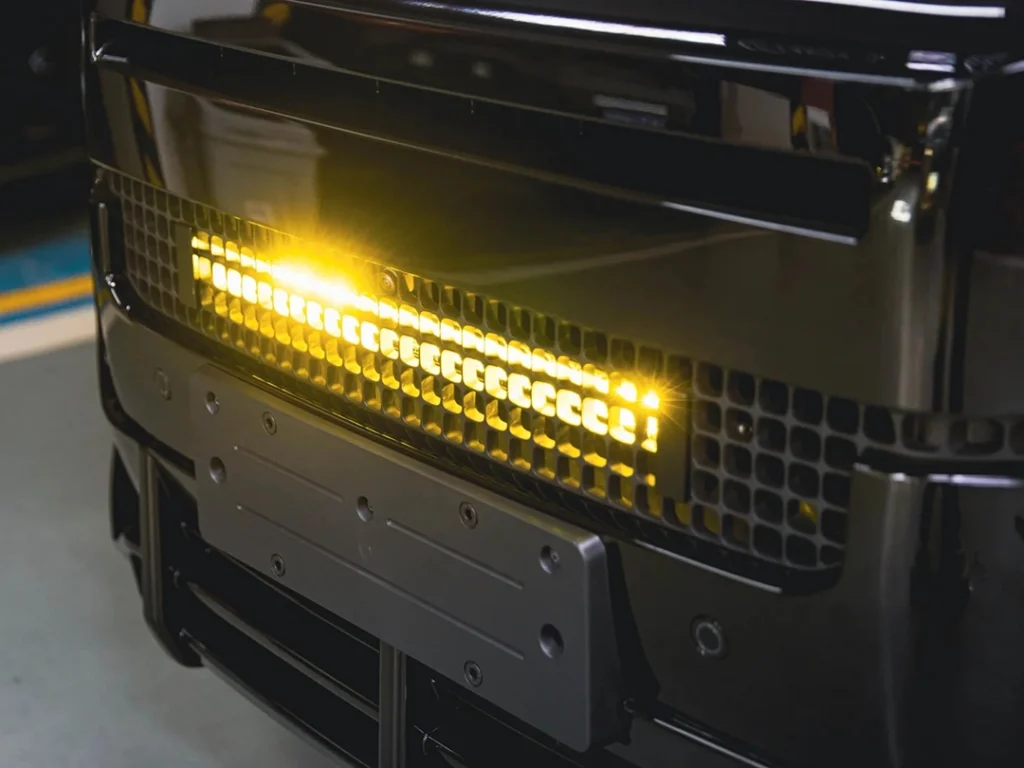

What Is Projector Headlamp? (The Simple, Useful Explanation)

A projector headlamp is a headlight system that uses a lens and an internal optical structure to shape and “project” light onto the road in a controlled pattern.

Here’s what makes it different from a basic reflector headlight:

- Lens-controlled beam pattern: The lens and shield create a defined cutoff line.

- Better light placement: More light goes onto the road where you need it, instead of spilling upward.

- Reduced glare potential: When installed and aimed correctly, projectors are easier to keep polite to oncoming traffic.

A key point many drivers miss: a projector setup is not “just brighter.” It’s more controlled. And control is what makes night driving feel calmer and safer.

Projector Headlamps vs Halogen: The Real-World Difference

“Halogen” is a bulb type. “Projector” is an optical design. People often treat them as opposites, but they’re not perfectly comparable. Still, in everyday terms, most drivers are comparing a typical stock halogen reflector system to a projector-based upgrade.

What you typically gain with projector headlights

- A crisp cutoff line (less stray light, less glare)

- More usable brightness (illumination where your eyes actually look)

- Better width and uniformity (less tunnel vision)

- Cleaner high beam performance when a bi-function setup is properly tuned

What you don’t automatically gain

- Perfect visibility in every weather condition (rain and fog still obey physics)

- Safety if the beam is misaligned

- Reliability if sealing and wiring are done carelessly

This is where many upgrades fail: people buy decent components, then lose the benefit through poor aiming, sloppy wiring, or weak sealing.

OEM Projector Headlights and the “Factory Feel” People Actually Want

When drivers say they want OEM projector headlights, they’re usually describing outcomes:

- OEM fit and finish (no broken tabs, no panel gaps, no stressed mounts)

- OEM reliability (no condensation, no flicker, no warning lights)

- OEM beam behavior (flat cutoff, correct height, no dazzling)

That “OEM feel” is a manufacturing mindset. A reputable projector headlights factory and a professional retrofit workshop treat the headlight as a system with three equal priorities:

- Optics (beam shape, cutoff, width, hotspot placement)

- Electrics (stable current, clean connections, proper coding)

- Sealing (air-tight, moisture-resistant, durable)

You can’t fake any of these with marketing.

OEM Projector Headlights Factory Mindset: Why Process Matters More Than Parts

In retrofit work, it’s common to hear a phrase like: a few parts, and most of the result comes from tuning. It sounds dramatic until you watch two cars with similar components end up with totally different outcomes.

The difference usually comes down to:

- How carefully the housing is opened and resealed

- Whether glue channels are cleaned properly

- Whether the projector is positioned and fixed under repeatable standards

- Whether wiring is soldered, insulated, and routed like OEM

- Whether coding is done properly (rather than using heat-prone add-ons)

- Whether aiming is performed in a controlled environment

If the goal is a “one-and-done” upgrade, the workflow must be standardized—because improvisation is how comebacks happen.

The Professional Retrofit Workflow (88-Step Discipline + 32 Completion Standards)

Below is a structured, real-world workflow for oem projector headlights retrofits—written for drivers, but grounded in professional practice. The details may sound meticulous. That’s the point. The best work often looks boring from the outside because it’s repeatable.

Intake, handover, and pre-check (the job starts before disassembly)

A professional retrofit begins with confirmation and documentation:

- Vehicle reception and handover confirmation

- Baseline inspection of existing headlamp condition and wiring integrity

- Work order confirmation (parts list, expectations, and scope)

- “Before” beam check and functional check (to prevent surprises later)

This is how you avoid the classic “it was already like that” situation—on both sides.

Disassembly: remove what you must, protect what you should

Many vehicles require bumper removal to remove headlamps safely. The goal isn’t speed; it’s control.

- Remove bumper and headlamp assemblies without stressing tabs or mounts

- Store hardware by location to maintain correct fitment and torque behavior

- Protect paint and clips to avoid cosmetic damage

Clean disassembly is invisible—until it isn’t.

Headlamp opening and glue removal: the “slow craft” that protects the housing

This is a quality separator.

A careful process typically involves two technicians and multiple tools, opening the headlamp gently by hand, then spending significant time removing adhesive cleanly—without scarring the housing or deforming the sealing channel.

Why it matters:

- A damaged sealing channel is a condensation problem waiting to happen

- Residual glue prevents even compression during resealing

- Scratches and warping ruin the “OEM look” permanently

Good opening work is not aggressive. It’s patient.

Parts confirmation and internal assembly: no guessing, no forcing

Before anything is mounted permanently, components must be verified:

- Projector module, shrouds, drivers/ballasts, wiring harnesses

- Clearances, mounting points, dust caps, heat space

- Compatibility with the vehicle platform and target beam spec

Then internal assembly begins:

- Module assembly and fixture preparation

- Projector positioning and alignment

- Preliminary level and cutoff verification before final fixing

Projector positioning and level confirmation: beam quality starts here

If the projector is even slightly off-angle inside the housing, you’ll see it on the road as:

- a tilted cutoff line

- uneven left/right distribution

- reduced width

- glare where there shouldn’t be any

This step is where “looks bright in the garage” turns into “drives great at night.”

Screw fixation philosophy: secure now, serviceable later

Professionals often tighten, loosen, adjust, and re-tighten repeatedly. It’s not indecision—it’s precision.

- Stable mounting under vibration and thermal cycling

- Serviceability for future upgrades or maintenance

- Consistent aim retention over time

A retrofit that can’t be serviced cleanly tends to age poorly.

Wiring: soldering, insulation, and stability (the unglamorous safety work)

Electrical work should be built for years of vibration, heat, and moisture.

- Proper solder penetration for stable current delivery

- Robust insulation strategy (multi-layer heat shrink is common)

- Strain relief to prevent fatigue failures

- Layout designed to minimize interference and protect high-voltage components

This is how you reduce flicker, random faults, and intermittent behavior.

Shroud trimming and refinement: millimeter work that prevents stray light

Shrouds aren’t only aesthetic. Poor fit can cause internal reflections, stray light, and a messy beam.

- Repeated test fitting

- Precision trimming for tight mating surfaces

- Ensure no light leakage around the projector assembly

It’s the detail that makes the beam look “clean,” not chaotic.

Product calibration: the part that turns components into performance

A “simple combination” of parts does not automatically produce a great beam. Calibration includes:

- Smart matching of components and optics

- Projector depth and alignment optimization

- Cutoff clarity and uniformity refinement

- Preparation for on-vehicle aiming (because bench alignment isn’t final)

This is where the upgrade becomes coherent.

Second calibration at a 7.6-meter aiming distance: where safety is decided

Aiming should happen in a controlled indoor environment at a standardized distance—7.6 meters is a common benchmark in professional setups.

This stage focuses on:

- Final horizontal leveling

- Beam height accuracy

- Width and hotspot placement

- Ensuring “brighter” does not become “glare”

Tiny adjustments matter. A few millimeters at the adjuster can change real-world comfort dramatically.

Computer coding (and why avoiding hot add-on decoders matters)

Modern vehicles often require system-level configuration.

A professional approach uses proper coding equipment to:

- Match light modes and vehicle behavior through programming

- Avoid heat-generating add-on decoders that can introduce risk

- Keep wiring intact (no cutting, no messy splices)

- Maintain a clean engine bay and inspection-friendly setup

This is one of the most overlooked steps in “OEM-feel” retrofits.

OEM-style routing and ballast/driver placement: clean, protected, repeatable

Good routing is not cosmetic. It prevents failures.

- Secure drivers/ballasts in optimal thermal and vibration locations

- Harness routing that avoids rubbing, water exposure, and sharp edges

- No exposed external wiring that makes the job look improvised

A tidy install is usually a reliable install.

Resealing: machine-applied sealant + air-tightness testing

Resealing is the difference between “great for a month” and “great for years.”

A disciplined sealing process typically includes:

- Even sealant application into the channel

- Assembly with correct pressure and alignment

- Air-tightness verification to prevent fogging and leaks

If a shop is confident enough to back sealing long-term, it usually means they trust their process.

Final inspection and delivery: 32-point completion confirmation

Professional delivery isn’t “turn on the lights and done.”

A structured completion standard typically covers:

- Beam pattern verification (low/high, symmetry, cutoff behavior)

- Fitment checks (gaps, mounting stability, bumper alignment)

- Electrical checks (no warnings, stable operation)

- Clean-up and detailing around the work zone

- Owner-facing explanation of operation and care

This is how a retrofit becomes a product-level experience.

Laser Projector Headlight: What It Is (and When It Makes Sense)

A laser projector headlight system generally uses laser-based light generation to achieve very high intensity—often for long-range high beam functions in premium applications.

Practical truths:

- Laser systems can deliver impressive throw and intensity

- They demand strong thermal management and safety engineering

- For many daily drivers, the biggest improvement still comes from a well-tuned low beam with excellent cutoff, width, and proper aim—not from chasing the most exotic light source

Laser is exciting. Process is what makes it livable.

The Practical Takeaway: “One-Step-Right” Projector Headlights Are Built, Not Bought

A great projector headlights upgrade feels effortless when you use it. That effortless feeling comes from work you never see:

- Careful opening and glue removal that protects the housing

- Precise projector positioning and fixation

- Serious wiring discipline with stable soldering and insulation

- Proper coding for modern vehicle compatibility

- Standardized 7.6-meter aiming for safe, wide, bright output without glare

- Robust resealing and air-tightness testing

- A repeatable delivery checklist with completion standards

If you want your retrofit to look and behave like OEM projector headlights, choose a workflow that treats the headlamp like a system—optics, electrics, and sealing—because the road will test all three.