Upgrading headlights is one of those mods that sounds simple—until you start worrying about heat, beam pattern, inspections, and whether you’ll accidentally break something the car was born with. The good news: most “headlight upgrade anxiety” comes from a few common misunderstandings (and a few genuinely bad products).

Below is a practical, no-drama guide to what matters when upgrading to projector headlamps, especially led projector headlamps, based on the questions owners ask most often.

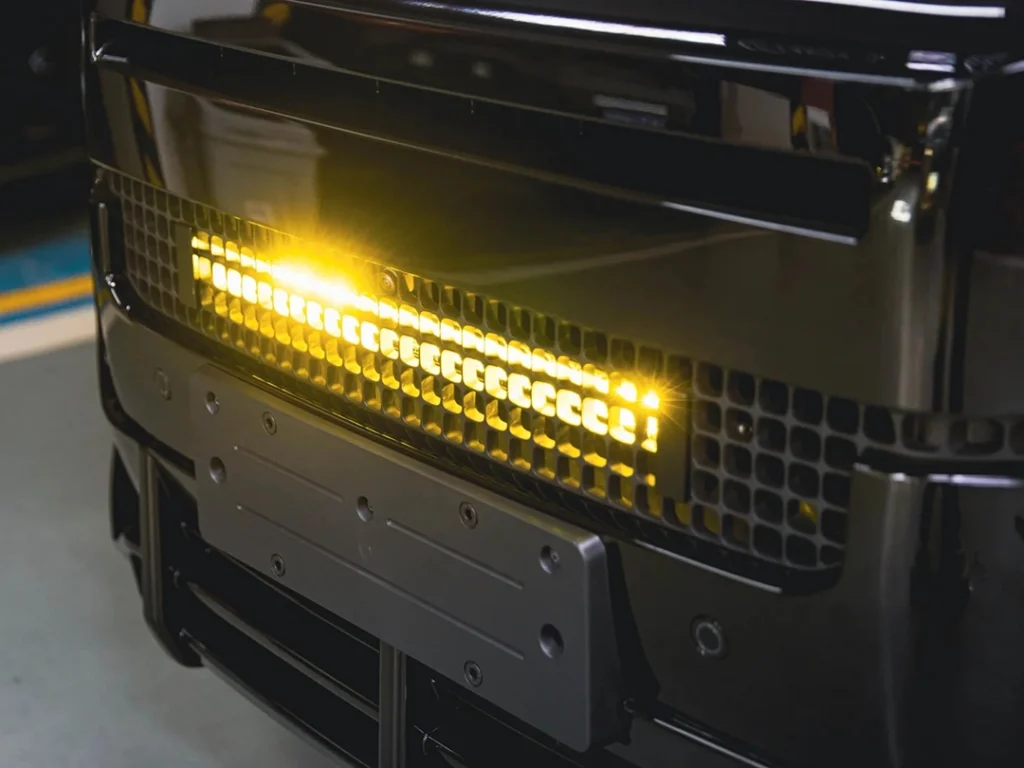

LED Projector Headlamps: Why Heat Management Is the Make-or-Break Factor

If there’s one thing worth caring about, it’s heat. Not because LEDs “run hot” in the way halogens do, but because LED performance and lifespan depend heavily on how fast heat is pulled away from the chip.

Cheap options often cut costs right where you don’t want them to: materials, thermal design, and quality control. When pricing looks too low compared with the market, it usually means either massive volume with compromises, or weak technical support and inconsistent build.

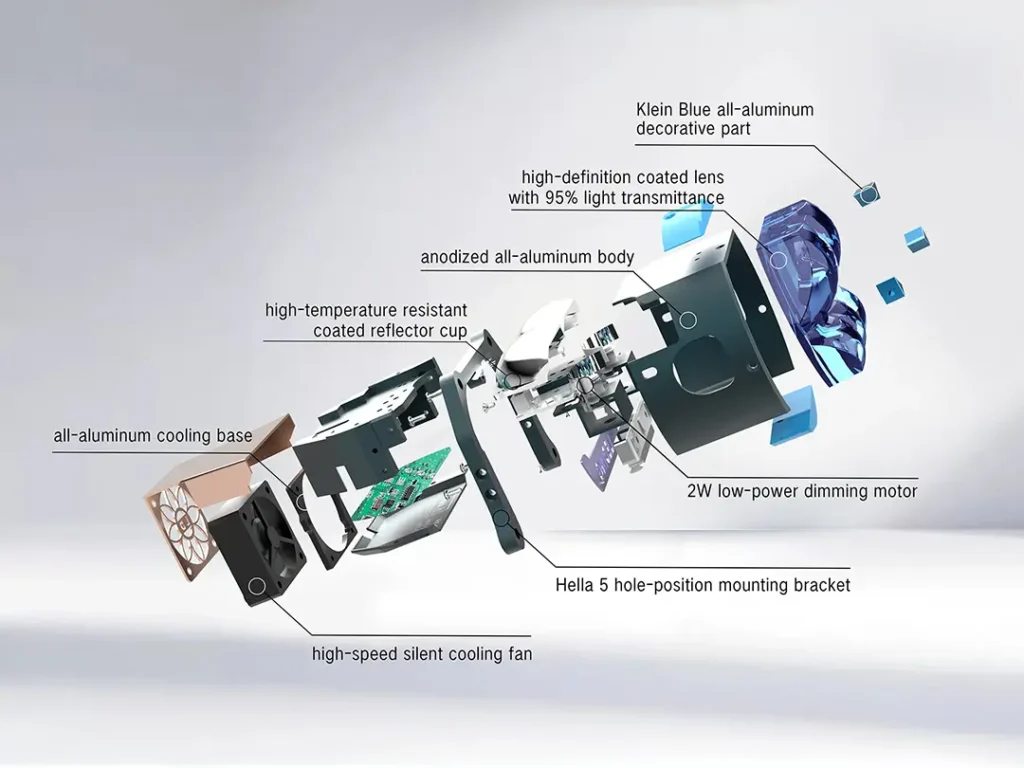

What good thermal design looks like (and where to check)

Heat management shows up in three places:

- Housing material (aluminum body)

- A one-piece integrated aluminum body dissipates heat far better than parts that are welded and then joined.

- When a metal structure isn’t truly integrated, thermal transfer can drop dramatically—real-world cooling performance can fall to a fraction of what you expect.

- Cooling fan (if the design uses one)

- The key isn’t “does it have a fan,” but can the fan maintain stable airflow over time without getting stuck or failing early.

- Better fans are simply less likely to become the weak link.

- Chip substrate / thermal path

- The LED chip sits at the heart of the light source. If heat can’t move away quickly, temperature builds up, which can cause premature failure (and in worst cases, melting nearby components).

- Better systems use higher-conductivity materials in the thermal path—good aluminum is common; copper solutions are even stronger.

Practical takeaway: higher-quality led projector headlamps often cost more for a reason—thermal design is expensive to do right.

Projector Headlamps That Keep OEM Functions: Will You Lose Features?

Many higher-trim vehicles come with OEM features like:

- auto-leveling (automatic height adjustment)

- steering-responsive lighting (cornering/adaptive functions)

A proper upgrade approach is to retain the original headlight assembly functions, aiming for a near “non-destructive” install—meaning:

- no hacking the factory wiring

- upgrades are performed within the original headlamp unit

- safety and reliability remain the priority

The result should feel like the car was meant to run the upgrade, not like it’s wearing a DIY experiment.

LED Projector Headlamps Cost: Is a Headlight Upgrade Always Expensive?

This is the big “beginner question,” and it’s fair.

Most modern upgrade paths focus on LED. The problem is that the market is flooded with low-quality LED bulbs without a projector lens design, which often leads to:

- scattered light (éblouissement)

- poor cutoff

- short usable distance

- unsafe driving conditions for you and oncoming traffic

Why projector design matters

A good projector setup (especially a bi-beam projector) is built to control the beam pattern. Done correctly, you get:

- a clear, sharp cutoff in low beam

- even road coverage

- less glare for oncoming drivers

- better usable brightness instead of “just looking bright”

A well-designed led projector headlamps system often includes independent cooling and temperature control so performance is stable on long drives.

Installing Projector Headlamps: Do You Have to Remove the Whole Headlight Assembly?

In most real-world upgrade jobs: oui.

Common retrofit processes (especially older HID-style retrofits) typically involve:

- removing the headlight assembly

- opening the sealed lens (often by heating to soften the sealant)

- installing the new components (projector + bulb/module + related hardware)

- resealing carefully to prevent moisture ingress

The point of resealing isn’t cosmetic—it’s what keeps the housing from fogging, leaking, or failing later.

Low Beam or High Beam: What Do You Upgrade First with Projector Headlamps?

Most upgrades focus on feux de croisement, because that’s what you use the most—and it’s also where glare control matters most.

Avec bi-beam projector headlamps, one projector can switch between low/high beam patterns. Combined with the vehicle’s original high beams, many setups achieve a “more coverage when needed” effect (often described as stronger multi-beam high-beam output).

Roadworthiness / Inspection: Will LED Projector Headlamps Fail Inspection?

In many places, inspection issues come down to beam pattern and color temperature, not the fact that you upgraded.

Two practical rules people follow:

- Keep color temperature reasonable (commonly ≤ 6000K) to avoid overly blue light and reduced visibility in rain/fog.

- Make sure the system uses a proper projector/optics setup so the light is focused with a controlled cutoff, not sprayed everywhere.

Also, regulations vary by region, but in practice: a clean cutoff and correct aim do more to keep you compliant than chasing “the brightest” option.

Aiming and Adjustment: What If You Don’t Know How to Aim After Upgrading?

A good installer should deliver the car with:

- low beam cutoff aligned and clear

- high beam focus concentrated (not scattered)

- uniform distribution across the lane

- real-world “road throw” verified and fine-tuned

Aiming isn’t a nice-to-have—it’s what turns “bright” into “useful and safe.”

Safety Concerns: Are Projector Headlamps Upgrades Dangerous?

When done correctly, the risk is low.

A few key points that calm most fears:

- Stock halogen bulbs often draw more power than many LED systems.

- Retrofit systems typically include drivers/ballasts to stabilize power.

- The main risk is bad wiring or incorrect connections, which is why professional installation matters.

Will upgrading cause a car fire?

It’s rare to hear of fires caused by proper headlight upgrades. When incidents do happen, it’s often linked to:

- using bulbs not matched to the car’s electrical/load requirements

- altering factory wiring improperly

- ultra-cheap components with poor thermal and electrical protection

Rule of thumb: don’t gamble on the cheapest option for something that affects nighttime visibility and electrical safety.

Key Takeaways (What to Remember Before You Upgrade)

- Heat management is the core quality marker pour led projector headlamps.

- A proper projector setup is about contrôle du faisceau, et pas seulement la luminosité.

- Professional installation matters most for sealing, wiring, and aiming.

- Keep color temperature sensible and aim correctly to reduce inspection trouble and glare.